Services

Our specialist engineers assess the strengths and weaknesses of the proposed project and provide options to achieve optimal technical solution and improve profitability. We provide a bankable techno commercial feasibility report to Owners covering following aspects critical for investment decision:

Development Planning

Facility configuration

Technology selection

Execution Model Development

Preliminary Cost Estimation

Environment Impact assessment

Risk assessment

Financial Closure

For qualified projects, Vistatech assists in financial closure of the project either by Direct equity participation or by institutional lending. With the comprehensive range of in house capacities, we add value to project in all stages and are able to make the most challenging projects viable.

Vistatech engages some of the most experienced engineers and deploys state-of-the-art technology to provide best in class solutions for asset development. The conceptual work includes studies in the early stages of project development for both Greenfield units and Brownfield modifications. The studies can include Field Development, Basic Engineering, Process Simulation, Budgeting and determination of techno-commercial viability of projects and provides decision support to the stakeholders.

During the concept phase, many options can be evaluated before a large investment of engineering time is made. Typically, a base case is established, and other options are compared to the base case. Process modeling is used to develop the options. Sometimes lead time for delivery of equipment items can factor into selection of the best option. Vistatech's extensive cost database is used to compare the options and to select the most economic path forward.

Vistatech London and Dubai have multi-discipline engineering resources and experience in developing the Conceptual and Feasibility studies into a Front End Engineering and Design (FEED) package. The FEED phase translates the customer’s design basis into definitive equipment design, materials of construction, controls, utilities, offsites, and tie-ins. Pyramid’s experienced team is able to clearly specify the technical requirements for the project and review the safety aspects of the facility.

During the FEED phase, the project schedule, tendering philosophy, risk mitigation strategy, work break down structure and detailed cost estimates are developed to plan the procurement and construction phase. All of the process engineering is completed along with the mechanical engineering requirements necessary to proceed to the Detailed Engineering and Construction phase.

The FEED deliverables include the following:

Final Heat and Material Balances (H&MB’s)

Equipment sizing, materials of construction and design temperatures and pressures.

Process control requirements, including any analyzers, programmable logic controllers, safety instrumented systems, etc.

Piping and Instrument Diagrams (P&ID’s)

Plot Plan

Process safety contingency analyses

Utility loads (e.g., steam, cooling water, waste water treating, etc.)

Interconnections with other units (onsite and offsite)

Vistatech provides a single point Engineering, Procurement and Construction Solution for Hydrocarbon Processing facilities complete with utilities and infrastructure.

Vistatech specialises in fast tracking projects and offers several EPC delivery models as below:

Lumpsum Turnkey

Cost Plus

FEED developing to EPC

Project investment

Vistatech also offers a range of production solutions suitable for quick deployment and operation on a single point responsibility basis. Most of these are pre engineered and modularised packages which can be shipped within a matter of weeks. Only the minimal site construction scope remains which can be managed by a small team or local contractors. Vistatech has its own modular fabrication yard close to Mundra port in Gujarat, Western India. Due to its proximity to jetty, Vistatech can ship large process equipment and modules weighing upto 800 tons to expedite projects.

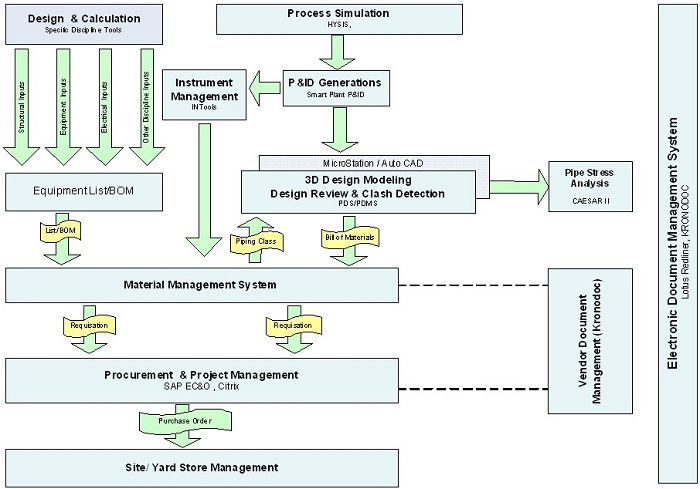

The key driver of EPC is the integrated management system shown below which enables mobilisation of thousands of personnel and myriad of material and services which go into a process plant.

Vistatech has a robust engineering team with track record of delivering more than 500 global assignments successfully. All the disciplines are in-house e.g.

Process Simulation

Basic engineering

PFD & P&ID Development

HAZOP & Safety Studies

Design of Process equipment

Plant hydraulics design

Specification for package systems

Instrument Specifications

Loss prevention system design

Operation & Maintenance Manual preparation

Commissioning & Troubleshooting

Static equipment e.g. distillation Columns, Vessels, Tanks, Heat exchangers and Reactors as per International codes & Practices (ASME , API, BS, EN, TEMA etc.)

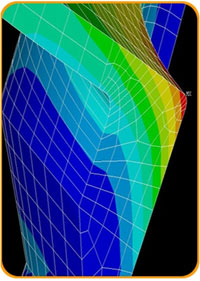

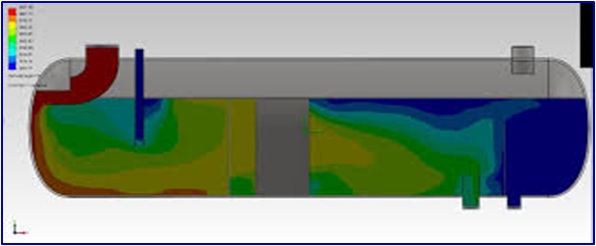

Design by Finite Element analysis, Stress, Thermal analysis & Fatigue life evaluation

Specification of Pumps and Compressors

Specifications for Package bought outs

Technical and commercial bid analysis

Vendor Document Approvals

Factory acceptance test witness

Development of Plot Plans and Equipment layouts

Strength Calculations

Flexibility analysis

Plant 3-D Modeling and clash detection

Piping material Specification

Support specifications

Isometrics and Bill of Materials

Advanced dynamic analysis

Development of infrastructure and facilities

Subsurface related civil work

Foundation Design

Structural analysis

Structural design

Offshore Design of Platform top sides

Engineering of Skids and Modular Structures

Structural 3-D Modelling

Automated fabrication drawing and MTO generation

Electrical System Study

System reliability and stability study

Substation Design

Hazardous Area Classification

Load Calculation and System design

Specifications for Electrical Equipment

Calculation of Electrical Bulk materials

General Arrangement & Interface inputs

Development of Control Logic

Preparation of Cause & Effect diagrams

Safety studies

Specifications of controls system

DCS/PLC engineering

Preparation of Field Instrument specifications

Layout and 3D modelling of Instrument system

Mounting and hook up drawings

Communication Network Design

Study Facilitation (HAZOP,HAZID,ENVID,BOWTIE etc)

Active Fire Protection Design

Passive Fire Protection Design

Firewater System Design

Blowdown / Flare Studies

Fire & Gas Mapping

Site Hazard Assessment

Fire & Explosion Studies

QRA Studies

Risk Assessment Studies

TR Impairment Studies

EERA Studies

ESSA Studies

HSEIA Studies

ALARP Demonstration

Cost Benefit Analysis

Finite Element Stress Analysis

Computational Fluid Dynamic Studies

Gas Dispersion & Explosion Analysis

Noise & Vibrational Studies

Fire & Gas Mapping (3D)

Flow Assurance Studies

Residual Life Assessment

Reliability Availability Maintainability (RAM)

Reliability Centered Maintenance (RCM)

Risk Based Inspection (RBI)

Safety Integrity Level (SIL) Assessments

Logistics & Transportation studies

Failure Modes Effects & Criticality Analysis (FMECA)

Life Cycle Costing

Baseline Environmental Studies

Environmental Risk Studies

Legislative Compliance Reviews

Preparation of Registers

Vistatech offers Modular Process Plants and has full multidiscipline engineering, procurement and fabrication capability.The range includes:

Oil & Gas Process Modules

Field Diesel units

Crude Oil Topping units

Refinery Modules

Fired Heater Modules

Piperack and Structural Modules

Large Pressure Vessels

Infrastructure

Total Facility Area 20,000 m², Covered Area 8,000 m²

Pressure Vessel Fabrication Shop

Pipe Spool Fabrication Shop

Structural Fabrication Shop

Electrical and Instrumentation Hook-up

Spool & Shop drawing office Spool & Shop drawing office

Shot Blasting, Heat treatment & Painting

Warehouse Shipping & Handling Warehouse, Shipping & Handling

Maximum Cargo size 12M W x 10M H x 30 M LG (750 T)

Vistatech offers a variety of development options for Oil & Gas Production and Refining facilities that provide the flexibility to maximise the return on investment. We have various business models to facilitate operator’s needs, by providing a range of solutions for exploiting production from their fields, with minimal capital outlay in the early period of field life.

There are several options:

Build-Own-Operate

Build-Own-Operate-Maintain

Build-Operate-Maintain

Build-Own-Operate-Transfer

Build-Operate-Transfer (BOT) or Build-Own-Operate-Transfer (BOOT) structure for projects has proved to be a valued approach for private participation in the field development. Vistatech can supply standard production systems on a lease basis, with or without operational support.

The various business models are structured so that Vistatech takes responsibility for the detailed design, construction, commissioning, operation and performance of a particular project in the operator’s field. Once operational, Vistatech receives a payment for providing the services in the form of a long-term contract. The final element of the contract can take the form of ‘Transfer’ (BOOT), where the operator has an option to purchase the equipment and take control of operations for the plant.

Vistatech has experience in all aspects of these business models and offers a very competitive and cost efficient method for Field Operators to realise early revenue from their field. BOT and related arrangements (e.g. BOOT Build Own Operate Transfer and BOO Build Own Operate) and have been very successful in opening up public infrastructure to the private sector finance, and have a number of advantages. They bring private sector disciplines to the project development and design process leaving public sector far less exposed to risks of cost overruns or below expected performance. By enabling focus on a particular facility they can be more readily financed and do not impose a burden on public funds, and have thus probably helped encourage financial flows. The costs of financing are relatively low, with the bulk of the capital cost being financed by bank lending at modest margins.